MI Wiring Cable does not burn

-

※ ETP Electrolytic Tough Pitch Copper

※ DHP Deoxidized High Phosphorus Copper -

Test result

BS 6387 (British fire resistant cables) certification 950℃ 3 hour rating

UL 2196 (American fire resistant cables) certification 1,010℃ 2 hour rating

IEC 60331-2 830℃ 2 hour rating

Techinical Superiority

-

Fire Resistant

MI wiring cable do not burn and endure

explosion. It continues to supply power during

fire and run the emergency fire protection

facilities. Inorganic cable does not produce

smoke, toxic gas or flame. -

High Operation Temperature

MI wiring cable withstands continuous operating temperatures up to 250℃. The cable can operate for periods up to the melting point of copper (1,083℃)

-

Flexibility

MI wiring cable can be bended without the change of electric characters.

-

Mechanical Strength

MI wiring cable withstands considerable abuses such as bending, flattening and twisting without electrical failure. In case of using in wooden building like temple, it is also resistant to rodent attack

-

High Corrosion Resistance

MI wiring cable has high resistance to corrosion. In case of copper corrosive environment, cables with LSF protective outer coverings are available.

-

Waterproof

MI wiring cable’s metal sheath is impervious to water, oil and gas

-

Excellent Earth Continuity

The copper sheath eliminates the need for a separate circuit protective conductor. The excellent low resistance copper sheath conforms to the requirements of the IEE Wiring Regulations

(BS 7671) -

Radiation Resistance

MI wiring cable is composed of inorganic materials, so it is suitable for installation in nuclear radiation environments.

-

Non Flammable Material

MI wiring cable is composed of non- flammable materials. In case of LSf outer covering minumal fuel is offered to the fire situation.

Economic Superiority

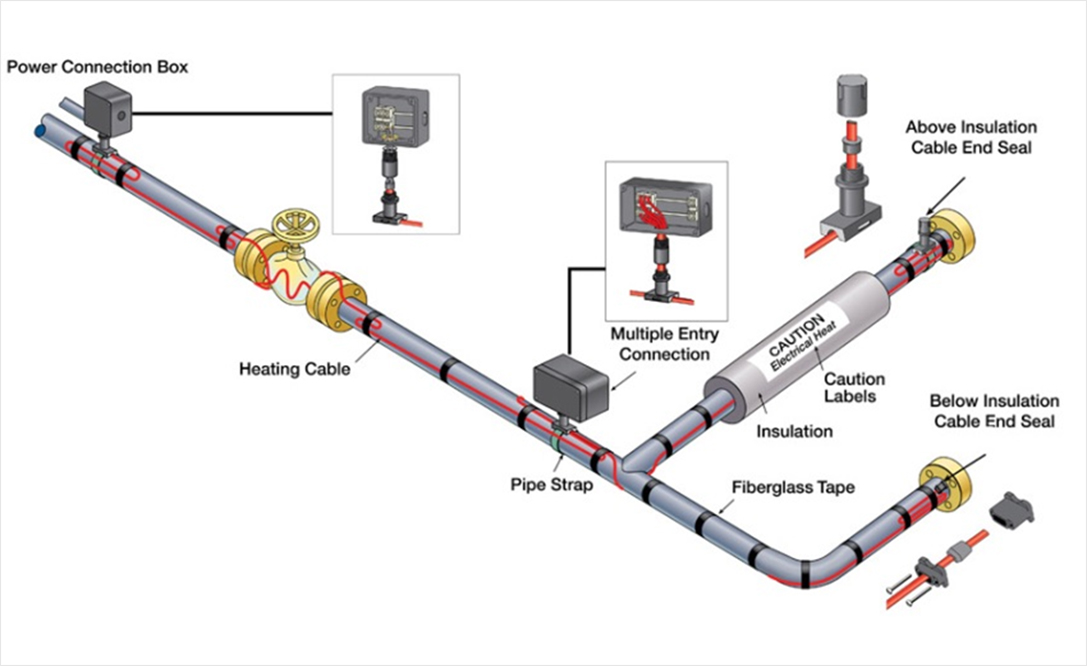

Decrease of Installation cost and period MI wiring cable is conduit-combined. Cost of separate conduit and installation fee decrease. No need of cable installation into the conduit brings down the construction period.

Self Earthing Effect MI wiring cable’s sheath is copper, and has self-earthing effect. No need of separate earth cable decrease the cost and installation period

Permanance MI wiring cable is made of inorganic materials, so the sheath, insulation and conductor remains sound regardless of time. Several years after initial installation, the cables could be re-used.

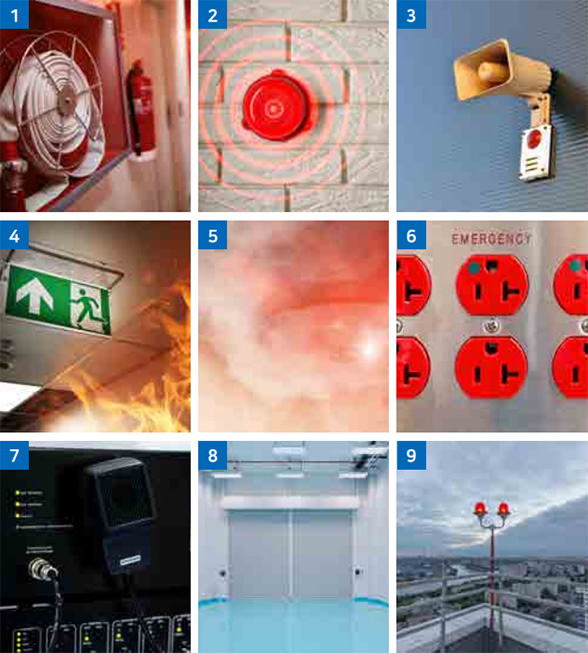

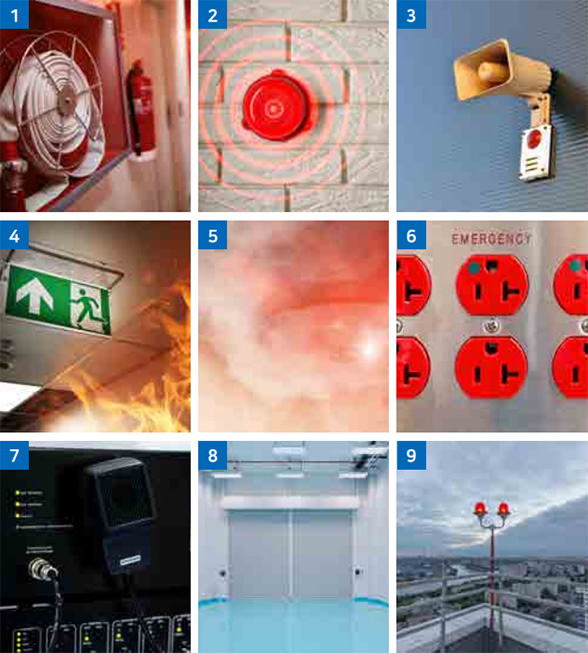

Required site of fire resistant cable

MI wiring cable burns 0m, 0% in every models

(Standard to pass in IEC 60332-3-24 : burns less than 2.5m)

Mandatory range of strenghened fire resistant cable usage : emergency power supply ~ Motor Control Center ~ Pump

1. Fire hydrant, sprinkler, water spray, foam extinguishing system

Power - Control panel - Motor

2. Emergency bell, automatic siren

Emergency power - starter power

3. Broadcasting facility

Emergency power - amplifier power

4. Guidance light

Emergency power - guidance light

5. Fire detection and alarm system

Emergency power - receiver, repeater power

6. Emergency outlet

Emergency power - emergency outlet

7. Wireless communication facility

Emergency power - amplifier power

8. Fire protection shutter

Emergency power - fire protection shutter

9. Aircraft warning light

Emergency power - lighting power - aircraft warning light

MI wiring cable burns 0m, 0% in every models

(Standard to pass in IEC 60332-3-24 : burns less than 2.5m)

Mandatory range of strenghened fire resistant cable usage : emergency power supply ~ Motor Control Center ~ Pump

1. Fire hydrant, sprinkler, water spray, foam extinguishing system Power - Control panel - Motor 2. Emergency bell, automatic siren Emergency power - starter power 3. Broadcasting facility Emergency power - amplifier power 4. Guidance light Emergency power - guidance light 5. Fire detection and alarm system Emergency power - receiver, repeater power 6. Emergency outlet Emergency power - emergency outlet 7. Wireless communication facility Emergency power - amplifier power 8. Fire protection shutter Emergency power - fire protection shutter 9. Aircraft warning light Emergency power - lighting power - aircraft warning light

Usage in Different Fields

-

General buildings

Ocean BuIlding / Singapore

Imbi Plaza / Indonesia

Time Square / Hong Kong

Kingkey Finance Center Plaza / China

Houses of Parliament / United Kingdom -

Hotels

Royal Station Hotel / United Kingdom

Marco Polo / Singapore

Sheraton / Qatar

Hilton / China -

Hospital

Papworth-Huntington / Singapore

Riyadh University / Indonesia

Teaching Hospital / Hong Kong

-

Subway and tunnel

Paris Metro / France

London Undergroud / United Kingdom

Tyne Tunnel / United Kingdom

Singapore Metro / Singapore

Taipei Metro / Taiwan

Montreal Metro / Canada

Kai Tak Tunnel / Hong Kong

Hangzhou Tunnel / China -

Oil and gas production

SINOPEC / China

BP / Canada

Shell / America

Shell / Dunlin

Esso / China

Elf / Erigg

Chevron / Ninian -

Power plant and nuclear facilities

Heysham / United Kingdom

Cockenzie / United Kingdom

Drax / United Kingdom

Dubai “G” Station / Dubai

Ras Abu Fontas / Qatar

Trombay / India

Tockai Marn / Japan

Shin Kori / Korea -

Airport

Heathrow International Airport / United Kingdom

Newcastle International Airport / United Kingdom

Frankfurt International Airport / Germany

Charles de Gaulle International Airport / France

Changi International Airport / Singapore

Shenzhen Baoan International Airport / China

Kuwait International Airport / Middle East

Dubai International Airport / Middle East

Narita International Airport / Japan

HongKong International Airport / Hong Kong -

Others

Ras Abu Foutas / Qatar

Castle Peak / United Kingdom

Doha east and west / Kuwait

Shell / Holland

ICI / United Kingdom

BP / Holland

Golden Eagle / Canada -

Aramco / Saudi

Neste / Finland

ADNOC / Saudi

National Bank / Malaysia

Motor Engine Plant / Wales