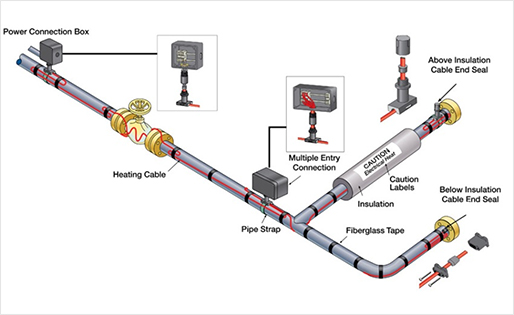

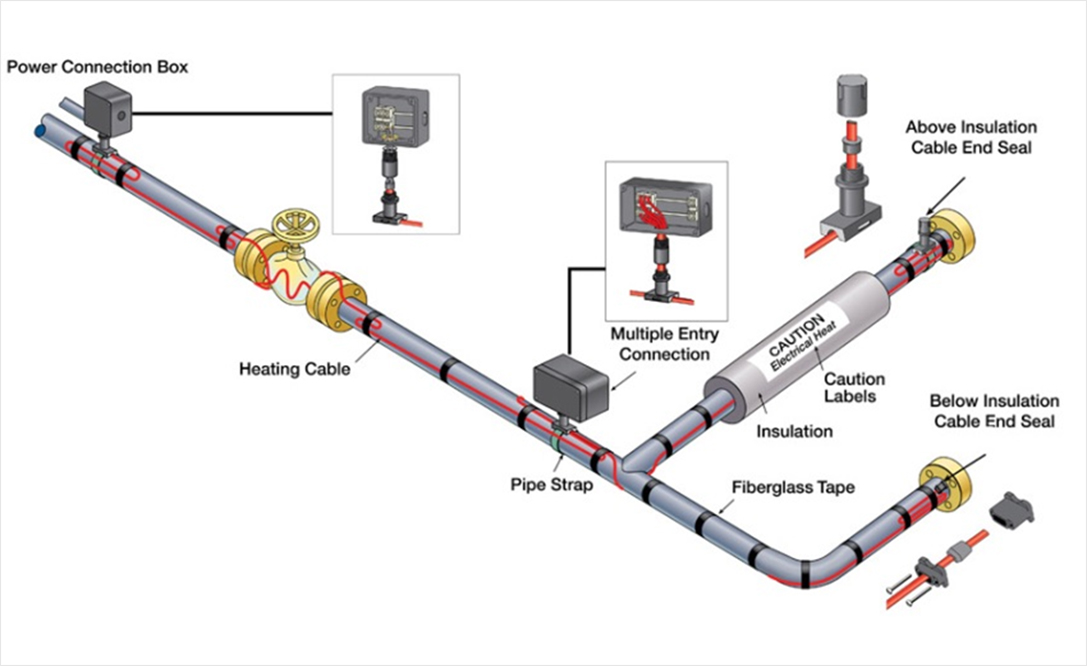

Electric heat tracing system

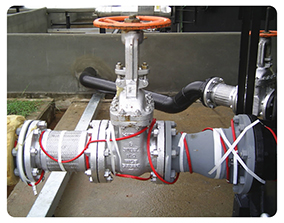

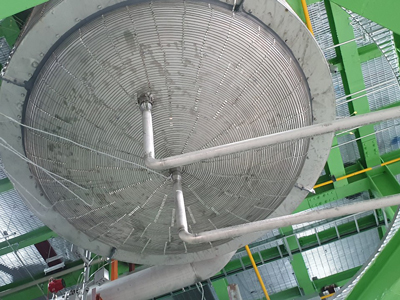

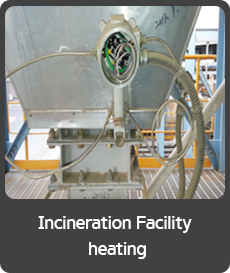

Heat tracing is a system to compensate the heat that is discharged. Through the insulation, it keeps the temperature in the pipe or storage container to preserve the material’s unique characters (temperature, viscosity, solidifying point, etc). The purposes are freeze prevention, temperature maintenance, and temperature rise. It needs to consider the pipe’s diameter, storage container’s size, insulation’s material and thickness, fluid’s specific heat, specific gravity, latent heat and so on. So it needs sophisticated design and control. Hot water or steam can also be used, but electric heat tracing is more in general use. It has more advantages in terms of performance, function, convenience, and cost. According to heating method, there are different kinds such as parallel type (self-regulating heating cable, zone heater), series type (MI heating cable, series heating cable), or SECT system (skin effect current tracing). According to the object, appropriate method needs to be selected. This system needs sophisticated design that considers heat-resisting property, durability, cost, etc.